Product Description

ZYTEST Deionized Water System

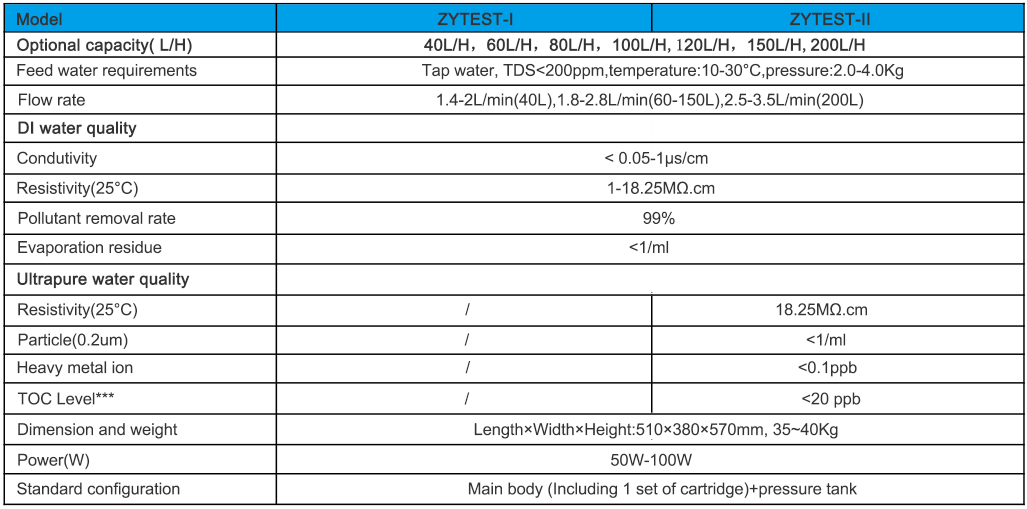

Our model ZYTEST is for deionized water system for hosptial biochemistry analyzer and hosptial clinical laboratory. ZYTEST with the conductivity meter ( <0.1um/cm) produced pure water as deionized water. This model is our hot sale machine with promotion price which is welcome to a large scale of clients'.

Parameter of Deionized Water System

*Automatic control, smart and safe;

*3 stage fitration pretreatment system PP+AC+PP to systematically and completely filtrate silt, rust, suspended matter, algo, colloid, particles, residual chlorine, odor, color, etc.

*More than 99% desalinization rate of RO membrane can efficiently remove salt ions, organics, microparticles, heavy metal ion, impollutant matter, etc.

*Filling specialty polishing resin ultrapure cartridge stably produce grade II ultrapure water(0.1-1us/cm).

*Automatic buzzer alarm: substandard water, water shortage.

*Safety system: post, water full shutdown, low pressure.

*Automatic RO membrane flushing to extend the working life.

*On-line monitoring conductivity meter to show the water quality timely.

Working Process

The technology process is divided into source water pretreatment system,reverse osmosis system and ultra-pure system.

5 stage purifying ultra pure water, purification methods and parameters to avail the purity and classify the impurities to be removed from the original water (tap water or natural one) from what one wants to generates the purified water.

1. Source water pretreatment system: PP fiber filter + AC filter + Softener

2. Reverse osmosis system: It has high removal rate more than 99% for high valent ions, colloids, bacteria and organic matter (including endotoxin) with molecular weight greater than 300Dalton.

3. Ultra pure system: Ion exchange resin using H + exchange cation out the water in the filter ,using OH- exchange anions out the water , the replaced H + and OH- combined to produce H2O, ultra-purified column filling the United States Dow UPW-450 Ultra-pure water for nuclear grade resin, the water resistance of up to 18.25 MΩ.cm.