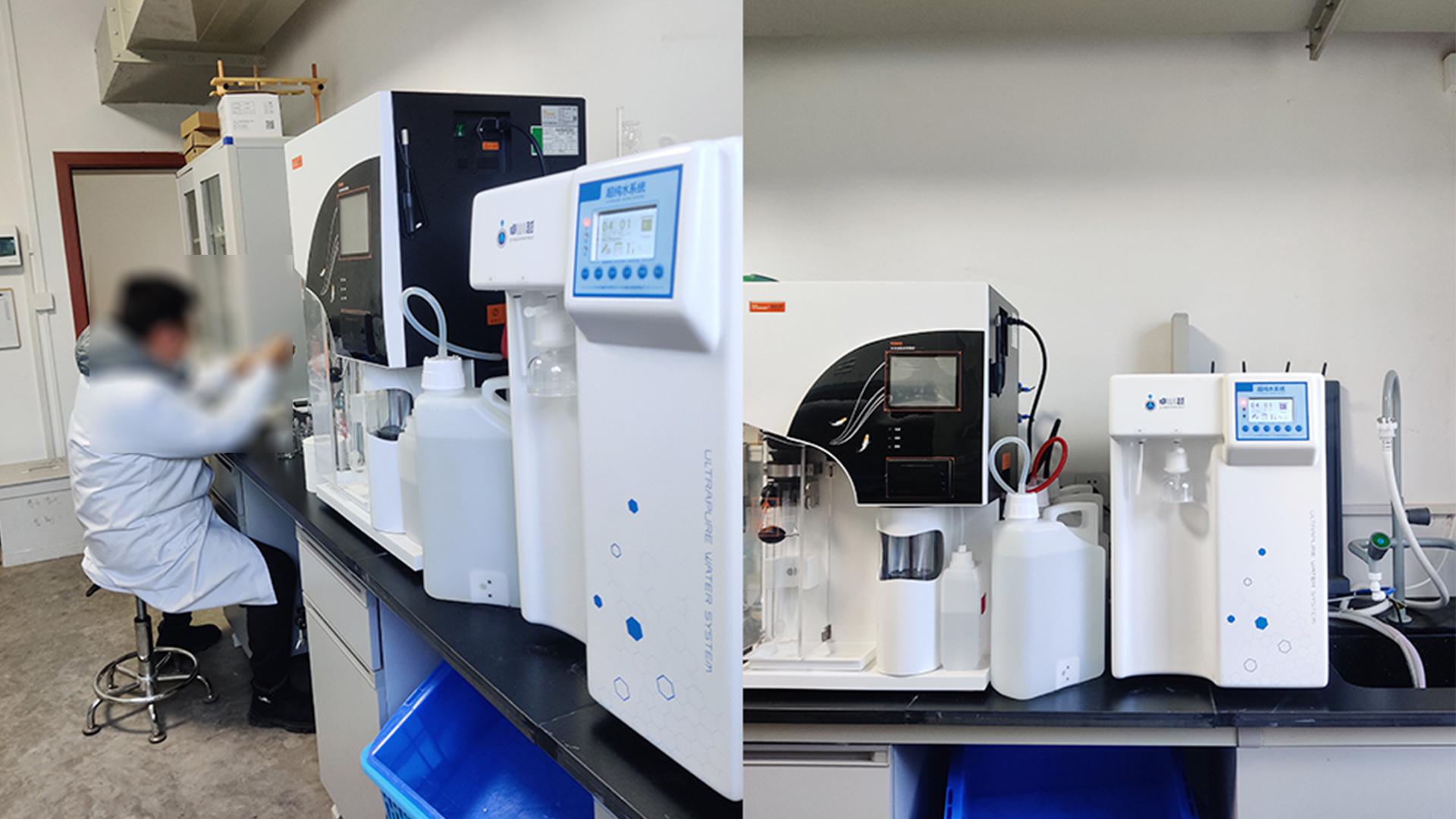

High Quality Deionized Water For Your Lab

ZHUOYUEE has extensive experience in ultrapure water system design and engineering. Specializing in the production of laboratory ultra-pure water machine, pure /ultra-pure water equipment,Slightly acidic electrolyzed water,water softener and other related water treatment equipment. Our ultrapure water equipment integrates cutting-edge fltration technologies, effectively eliminating conductive media, colloidal substances,gases, and organic matter from water.

What is an Ultrapure Water System?

An ultra-pure water system is essentially a multi-stage water purifcation system deployed to eradicate all or nearly all pollutants residing in raw water.Customarily,ultra-pure water systems eliminate contaminants in multi-stage processes involving reputable technologies like reverse osmosis, ion exchange,UV water sterilization, and electrodeionization.ZHUOYUEE personalized ultrapure water systems with intelligent designs and varied production capacities to help distinct industries gratify their demand for UPW. These high-output systems typically produce high-purity water characterized by a resistivity of 18.2 MOhm-cm and an organic carbon concentration of <50 ppb.

How Is Ultrapure Water Used?

Ultrapure water serves as a critical reagent in a wide range of laboratory settings within both the semiconductor and pharmaceutical industries. While most regularly found in these two industries, the purification level of ultrapure water makes it ideal for use in any type of highly sensitive lab work.

Ultra-Pure Water Purifcation Process

The RO system, complemented by a bactericidal UV system, serves as crucial pretreatment for the electrodeionization system. To prevent biofilm formation and airborne contamination, the resultant pure water is stored in a polyethylene tank. The purifed water undergoes a final treatment, exposing it to UVlight radiation and post-treatment cartridges, ensuring the elimination of all organic and ionized pollutants.Alternatively, a widely embraced ultra-purifcation method involves a series of steps, starting with activated carbon flters, pre-chlorination,antiscalant dosing, and cartridge filtration for effective pretreatment. Subsequently, the water undergoes multi-stage ROfltration,culminating in a polishing phase with an electrodeionization system, resulting in the production ofUltra-Pure Water (UPW)."

Applications

In a wide range of applications across numerous industries, ultrapure water plays an essential role. Some of the most common uses for ultrapure water include:

High-performance liquid chromatography (HPLC)

Gas chromatography—mass spectrometry (GC-MS)

Graphite furnace atomic absorption spectrometry (GFAAS)

Liquid chromatography—mass spectrometry (LC-MS)

Immunochemistry (ICC)

Polymerase chain reaction (PCR)

Clinical analysers

Mammalian cell culture

Trace analysis

Besides these typical applications, ultrapure water assists in helping to address a number of issues. Some problems solved by ultrapure water include:

Bacterial contamination

Corrosion

Dissolved gases

Dissolved solids

Organics silica

Suspended solids

Total organic carbon