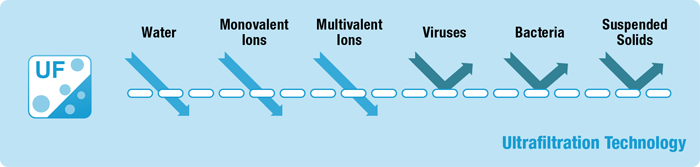

ZYCL Ultrafiltration (UF) water plant is a high-tech of 21st century which uses membrane seperation technology of differencial pressure to filtrate the harmful matters of silt, rust, suspended matter, colloid, bacteria, endotoxin and macromolecular, and remain minerals that are benificial to the human body. The recovery rate of UF plant can arrive at 95%, so it's the best choice for commercial, drinking, food, beverage, medical and environmental industry.

Technical Parameters :

| Water yield: | 0.5-100m³/h | |||

| RO membrane pore size: | 0.001-0.01um | |||

| Working pressure: | 0.2-0.4 MPa; | |||

| Water temperature: | 10-40℃ | |||

| Washing pressure | <0.1MPa | |||

| Washing flow | 200L/m2/hr | |||

| Washing frequency | 15-60min | |||

| Washing time | 30-60sec | |||

Working Flow:

* Automatic&Manual control.

* Quartz sand filter: filtrate silt, rust, colloid, suspended matter, algo, etc.

* Active carbon filter: adsorb residual chlorine, pigment, odor, etc.

* Antiscalant: remove Ca2+ and Mg2+ to prevent scaling and change hard water to soft water.

* Security filter: 5um PP cotton.

* UF module: 0.001-0.1um; filtrate bacteria, endotoxin, macromolecular matters, and save minerals.

Model List:

| No. | Model | Water Yield (L/H) | Voltage/ Power (V/Kw) | Body Size (L*W*H mm) | Water Tank (L/Material) |

| 1 | ZYCL-500 | 500 | 380/1.5 | 1500*600*1100 | 500/PE/SS |

| 2 | ZYCL-1000 | 1000 | 380/1.5 | 1500*600*1100 | 1000/PE/SS |

| 3 | ZYCL-2000 | 2000 | 380/1.5 | 1650*800*1200 | 2000/PE/SS |

| 4 | ZYCL-3000 | 3000 | 380/1.5 | 1650*800*1200 | 3000/PE/SS |

| 5 | ZYCL-4000 | 4000 | 380/2.0 | 1650*800*1200 | 4000/PE/SS |

| 6 | ZYCL-5000 | 5000 | 380/2.0 | 1650*800*1200 | 5000/PE/SS |

Features:

◎Low fouling Hydrophilic UF membrane

◎Excellent filter performance with high flux

◎High removal efficiency of bacteria and viruses

◎Periodically back washed and air scoured for consistent performance

◎Simple, vertical, modular design allows low cost, compact systems

◎Fully automated control system for backwashing process

◎Advanced custom designed Control Cubicle

◎Stainless / carbon steel equipment frame

◎Permeate, back pulse pumps, membrane aeration blowers and associated valving mounted on equipment frame

◎Control panel with standard PLC and HMI interface mounted on equipment frame.

◎High end electrical actuated operating valves.