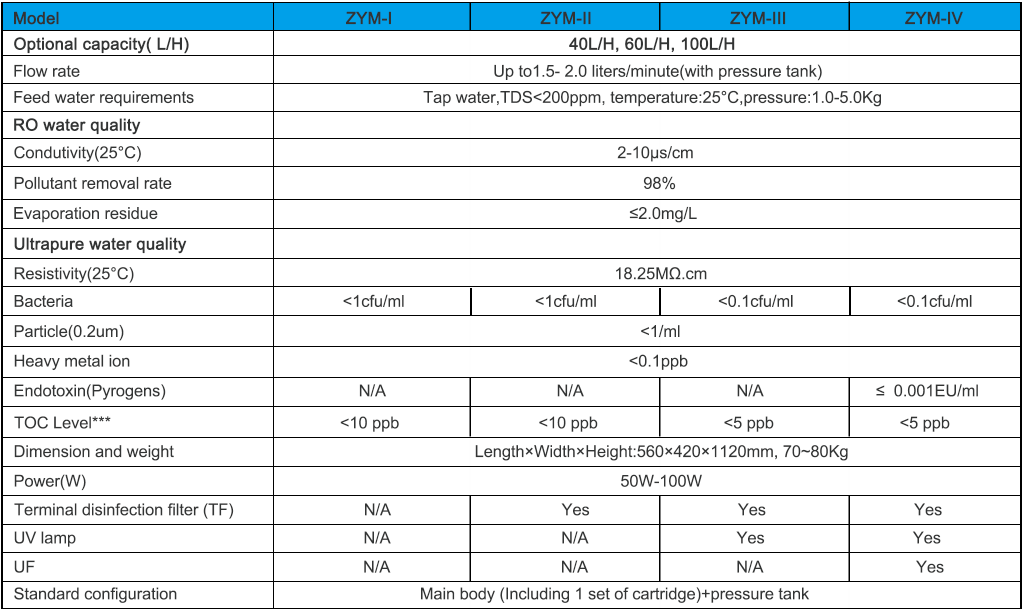

ZYM Deionized Water Treatment Plant For Lab

The model ZYM series produce the triple distilled water plant for lab with resisivity 18.25 MΩ.cm , which is triple distilled water 100% pure H2O without any minerals .

1.Ultra-pure water circulation to extend the life span of consumable parts within ultra-pure water purification system.

2.Automatic RO membrane anti-fouling flushing and manual forced flushing procedures to extend the life span of RO membrane.

3.Comprehensive system maintenance and safety alarm:

4. Equipped with USB Host interface to support historical alarm records and water taking record data export function, to

facilitate the later access to historical operation conditions data.

5.Adopt more advanced, user-friendly membrane push button to take water.

6.Semi-transparent medical grade PP material do not produce secondary pollution.

7.Humanization design of manual/automatic water taking mode,Timing(1-99min),customization water taking (0.1-18.25MΩ.cm)

The technology process is divided into source water pretreatment system,reverse osmosis system and ultra-pure system.

5 stage purifying system as below , purification methods and parameters to avail the purity and classify the impurities to be

removed from the original water (tap water or natural one) from what one wants to generates the purified water.

1. Source water pretreatment system: PP fiber filter + AC filter + Softener

2. Reverse osmosis system: It has high removal rate more than 99% for high valent ions, colloids, bacteria and organic matter

(including endotoxin) with molecular weight greater than 300Dalton.

3. Ultra pure system: Ion exchange resin using H + exchange cation out the water in the filter ,using OH- exchange anions out the

water , the replaced H + and OH- combined to produce H2O, ultra-purified column filling the United States Dow UPW-450 Ultra-pure

water for nuclear grade resin, the water resistance of up to 18.25 MΩ.cm.

Product exhibition