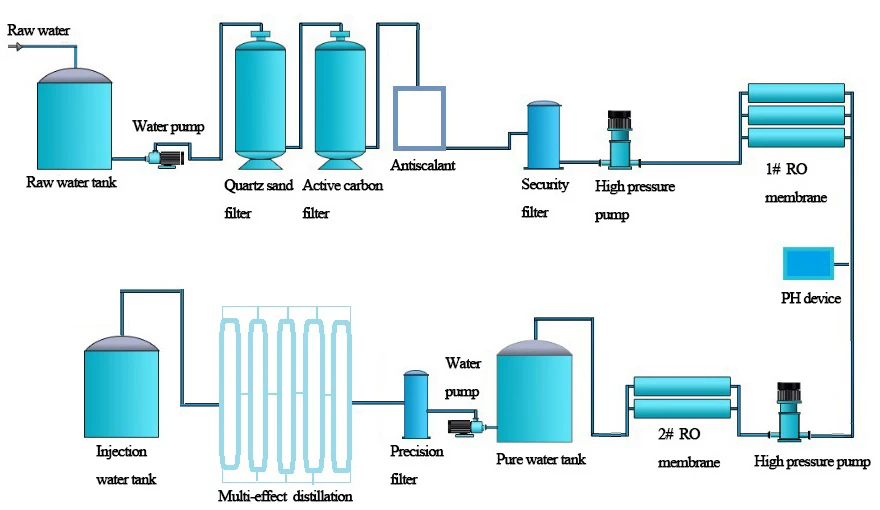

ZYGMPRO--The core technology of purified pharmaceutical water equipment adopts double-stage reverse osmosis and multi-effect distillation technology to design targeted high-quality pure water which can be used for pharmaceutical industry, hospital, laboratory diagnostic reagents, etc.

The entire system is made of SUS304L or SUS316L all stainless steel material combination, and before the water point must be equipped with ultraviolet,ozone disinfection device or can also be pasteurized.

1. Feed water: Meet the sanitary standards for drinking water (pressure 0.2-0.5MPa); conductivity ≤ 500μs/cm; total hardness <300ppm.

2. Power supply : AC380/220V 50HZ, three-phase five-wire, reliable grounding.

3.Temperature: 5-40 °C; Atmospheric pressure: 700Kpa-1060Kpa; Relative humidity: ≤ 80%.

4. Desalination rate ≥99%.

5.The maximum operating pressure: ≤ 1.5Mpa.

6.Installation site requirements: Smooth ground with a waterproof layer, a smooth floor drainage.

7. Avoid direct sunlight, strong magnetic field interference environment.

1. Automatic PLC touch screen.

2. Raw water pump: provide pressure to quartz sand filter and AC filter.

3.Quartz sand filter(equips Auto. flushing system): get rid of silt, rust. turbidity, suspended matter, organic matter, agla, colloid, etc.

4. AC filter(equips Auto. flushing system): adsorb residual chlorine, color, off-flavor and parts of organics.

5. Antiscalant: efficiently prevent the formation of scale, microbial glue and increase the machine's desalinization rate and water production.

6. Security filter(SUS; 5um): filtrate impuritiea and extend the working life of RO membrane.

7. Main engine: 2 stage RO membrane, high pressure pump, resistivity and conductivity meter, high&low pressure production, concentrate water flow, pure water flow, inlet solenoid valve, flushing solenoid valve, SUS304/316Lmainframe, etc.

8. RO membrane: desalinization and bacteria, endotoxin removal rate > 99%.

9. PH control apparatus: precisely adjust the pure water's PH after first stage RO membrane.

10. Disinfection system: pasteurization, electric heating, chemical sterilization, UV lamp, ozone generator, etc.

11. Multi-effect distillation: distill pure water.

12. SUS304/316L sterile water tank: equips pressure-type liquidometer, rotary spray cleaning, air filter, etc.

13. Reverse-flow system: convey pure water from sterile water tank to intake point; and then, recycle back to sterile water tank by SUS pure water pump. It can prevent the breed of bacteria and microorganism. microorganism.

Basic configuration:

(1) Pretreatment + Primary Reverse Osmosis + Secondary Reverse Osmosis + Sterilizer + Circulatory System

(2) Pretreatment + Primary Reverse Osmosis + EDI Equipment + Sterilization Device + Circulatory System

(3) Pretreatment + Primary Reverse Osmosis + Secondary Reverse Osmosis + EDI Equipment + Sterilization Device + Circulatory System

Customization is available

* Medical devices, Medical preparations, invitro diagnostic reagents, medical sterile water;

* Pharmaceutical water, biological analysis, blood purification, hemodialysis, biochemical product water;

* Disinfection room, and hospital supply room.